Palletizers

Custom

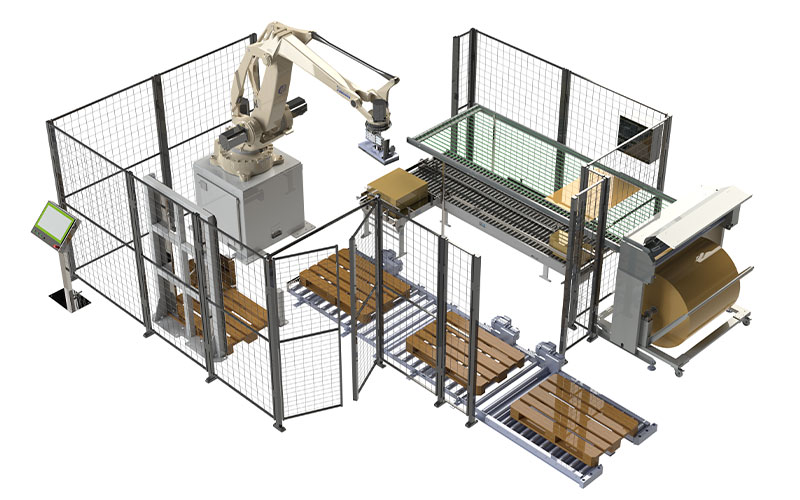

Robot Palletizer

Robot Palletizer

BK Automation’s robot palletiser offers an excellent solution for stacking boxes, crates, bottles, cans and bags on pallets. For the best end result, it is important to map out the customer-specific palletisation requirements and limitations. Through close cooperation with the customer, the sales manager and engineering, the detailed information is processed into the most optimal palletiser solution.

We process answers to these question into the design.

What will you be palletising and how?

-

Boxes, trays, crates, buckets and more

-

In patterns including columns, interlocking, staggered

-

With or without slip and grip sheets.

Benefits

-

Very user-friendly

-

Cost saving

-

Small footprint

-

No safety fencing

-

Quick start-up

-

Low maintenance

-

Robust design

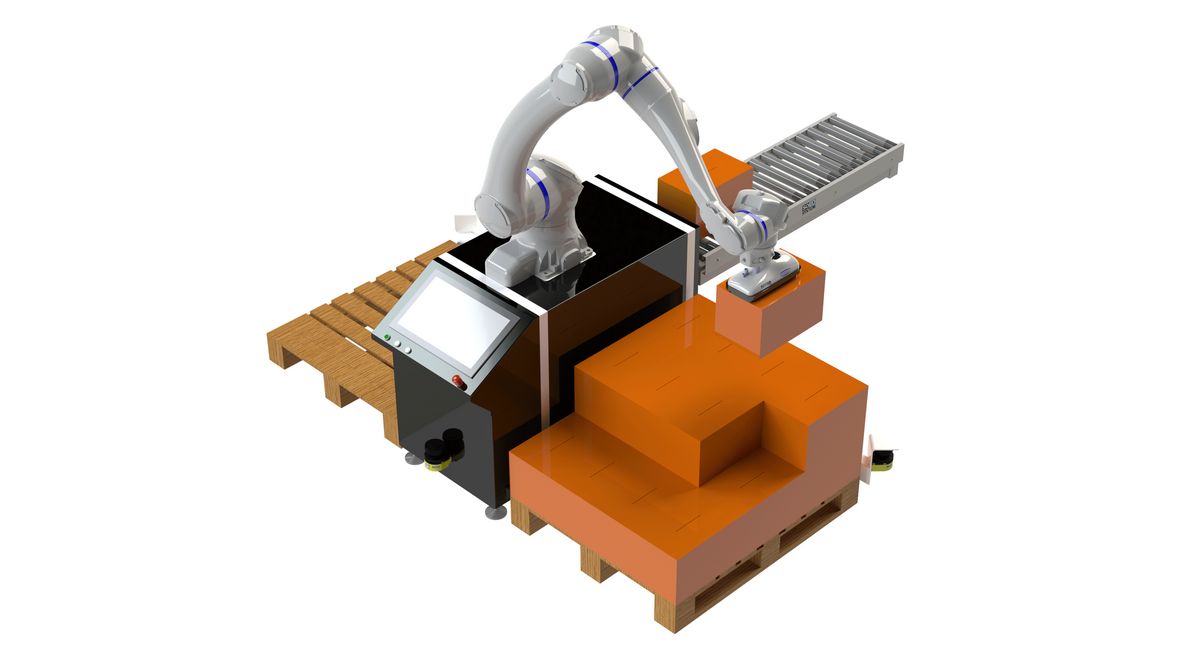

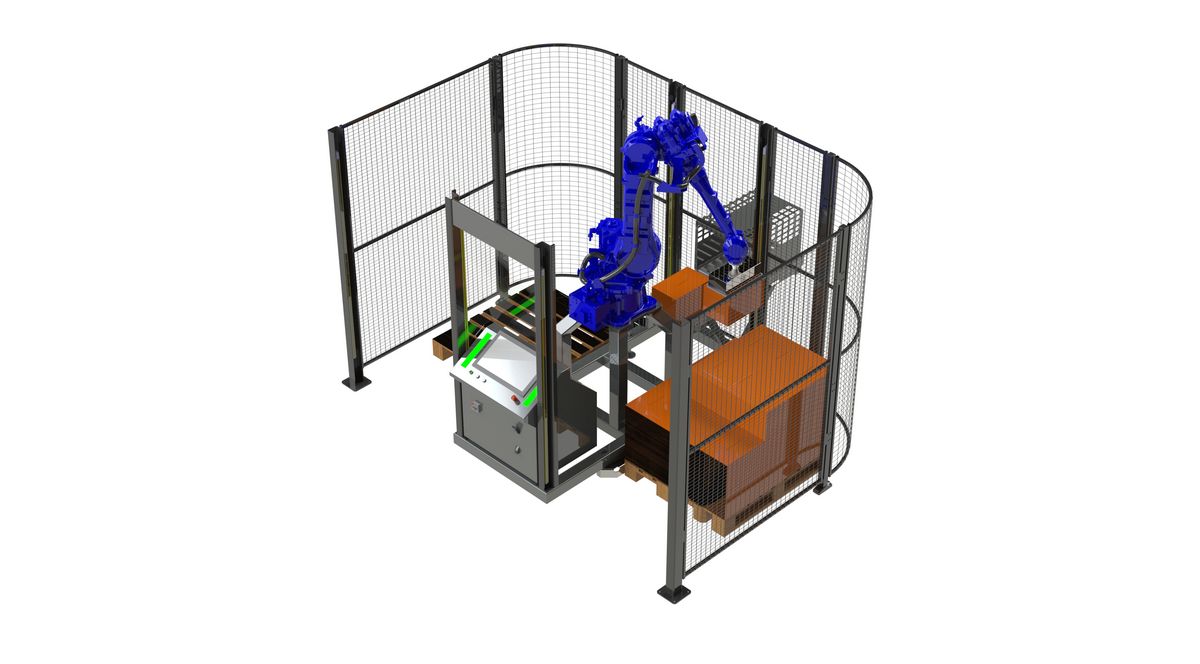

Cobot Palletizer

Single and double floor Position

Single and double floor Position

With its single- or double-load position, the Cobot Palletiser is the smallest palletising cell in the portfolio. With a high loading capacity, this palletiser is able to palletise the required products in a very small footprint.

Safety screens are required and it takes just a few steps to get the system ready for operations. The pallets are fed in and out using a forklift or a pallet truck. The cell is delivered turnkey and is quickly operational. Supplied as standard with the innovative software.

Cobot | Yaskawa HC10/20/30 |

Speed | Up to 12 boxes per minute |

Max. weight box/crate | Up to 20 kg |

Max. pallet height | Up to 2,000 mm |

Machine dimensions (mm) | 2944 (Width) x 1573 (Depth) |

The standard Cobot Palletiser can be expanded as standard with

-

Slip sheet magazine

-

Automatic pallet infeed and outfeed with AGV

-

(Automatic Guided Vehicles)

-

Stainless steel construction

Benefits

-

Very user-friendly

-

Cost saving

-

Small footprint

-

No safety fencing

-

Quick start-up

-

Low maintenance

-

Robust design

-

Moveable

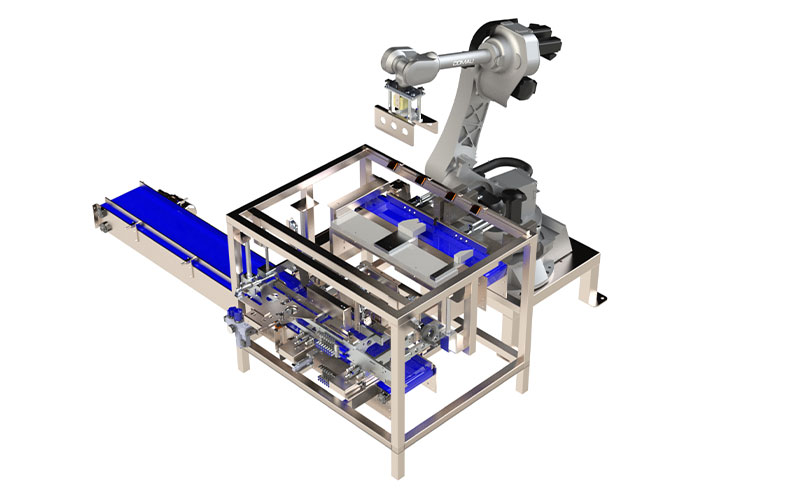

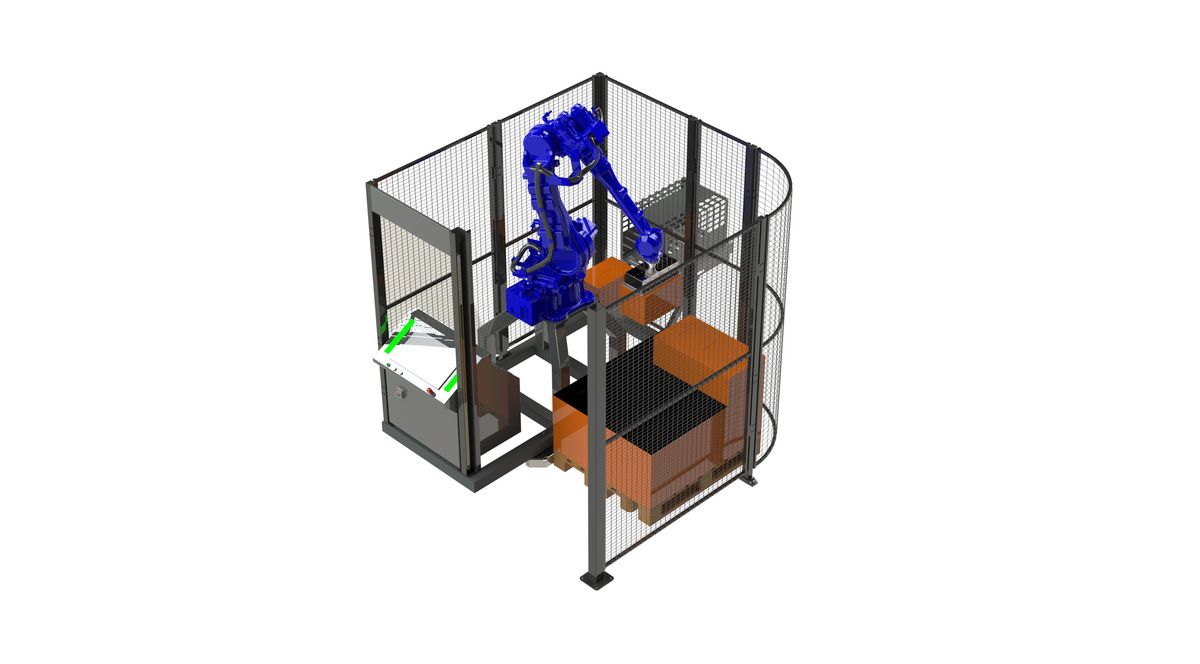

Compact Robot Palletizer

Single Floor Position

Single Floor Position

With its single-load position, the Compact Palletiser is the smallest palletising cell in the portfolio. It’s the perfect solution for palletising a single production line. Boxes and/or trays are lifted and palletised using vacuum. The pallets are fed in and out using a forklift or a pallet truck. The cell is supplied fully pre-assembled and is placed and started very quickly and easily. Standard equipped with innovative software; with remote control as an optional extra at no additional cost.

Cobot | Yaskawa GP25/GP50/GP88/PL80 |

Speed | Up to 24 boxes per minute |

Control Panel | 21" HMI |

Max. weight box/crate | Up to 50 kg |

Max. pallet height | Up to 2,000 mm |

Machine dimensions (mm) | 2322 (Width) x 3240 (Depth) |

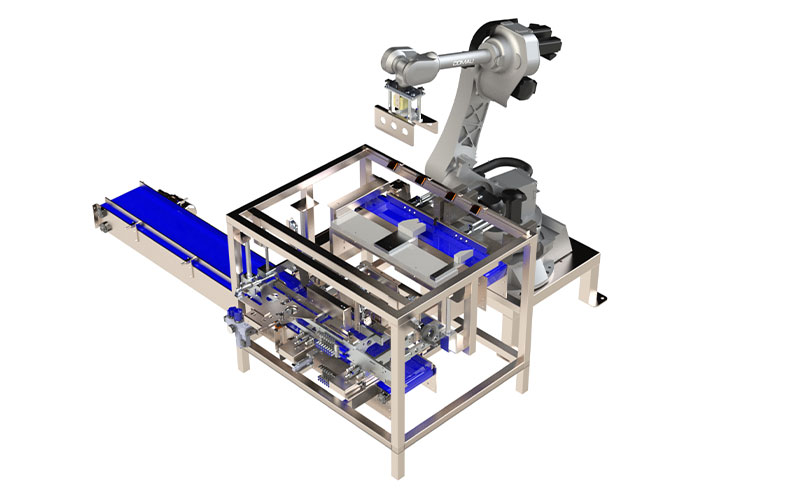

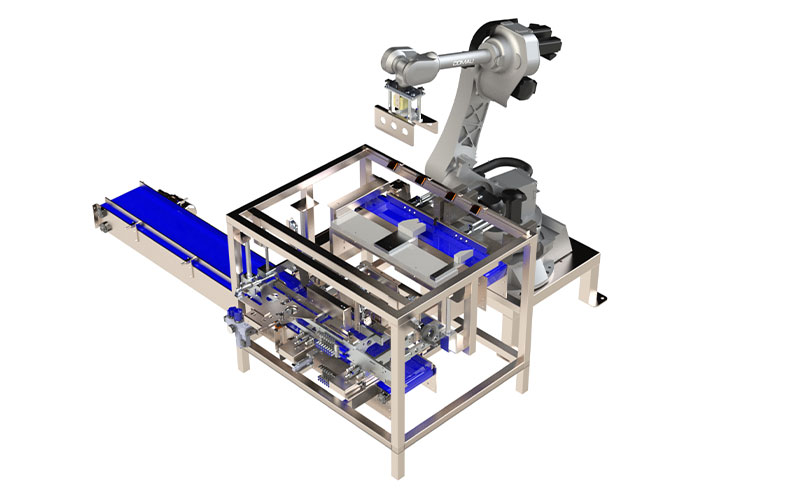

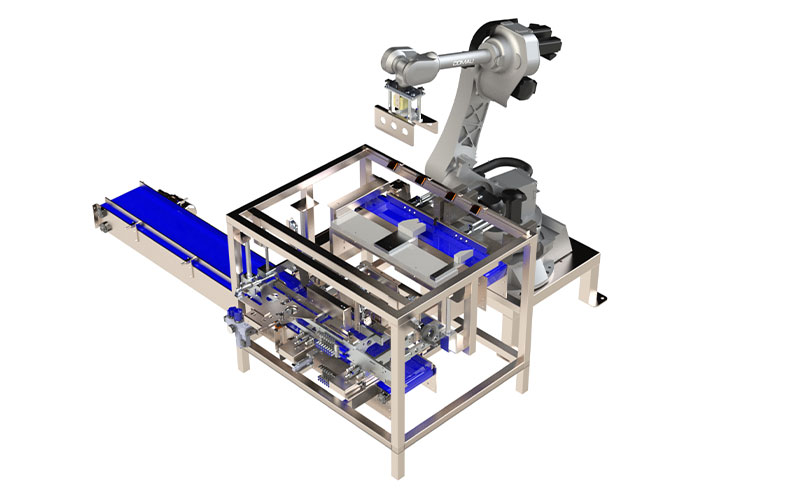

Compact Robot Palletizer

Dual Floor Position

Dual Floor Position

With its dual-load position, the Compact Palletiser makes it possible to palletise uninterrupted on a very small footprint. With two pallet stations, the robot completes one pallet before switching to the other, meaning there is always time to replace a pallet without stopping the cell.

The pallets are fed in and out using a forklift or a pallet truck. The cell is delivered turnkey and, based on a simple protocol, is placed and started quickly and easily. Standard equipped with innovative software; with remote control as an optional extra.

Robot | Yaskawa GP25/GP50/GP88/PL80 |

Speed | Up to 24 boxes per minute |

Control Panel | 21" HMI |

Max. weight box/crate | Up to 50 kg |

Max. pallet height | Up to 2.200 mm |

Machine dimensions (mm) | 3535 (Width) x 3250 (Depth) |

The standard Cobot Palletiser can be expanded as standard with

-

Slip sheet magazine

-

Continuous production by switching pallets without stopping the palletiser

-

Automatic pallet infeed and outfeed with AGV (Automatic Guided Vehicles)

-

Forked grabber with support underneath the box

Benefits

-

Very user-friendly

-

Cost saving

-

Small footprint

-

No safety fencing

-

Quick start-up

-

Low maintenance

-

Robust design

Modular system

AN OVERVIEW OF POSSIBILITIES WITHIN THE MODULAR SYSTEM

Automatic sheet magazine

Automatic infeed and outfeed

Control card integrated into the robot base

HMI panel in the screens

Light curtains

Pallet magazine

Sliding doors

Slip sheet magazine

Forked grabber with grabber belt

All our solutions

All our solutions

Click on the photo for more info